What is the Difference Between MV and LV Switchgear?

Understanding the distinction between medium voltage (MV) and low voltage (LV) switchgear is crucial for professionals working in power systems, facility management, and industrial automation. These components serve as the backbone of electrical distribution systems, but they are designed to operate at different voltage levels, in varied environments, and with distinct safety and performance requirements.

Core Concept Explanation

LV switchgear typically operates at voltages up to 1,000 volts AC (or 1,500 volts DC), whereas MV switchgear handles voltages ranging from 1kV up to 36kV or even higher, depending on regional classifications. The main function of both types is to control, protect, and isolate electrical equipment, but their use cases and internal technologies differ substantially.

Key Functions:

- Interrupt fault currents

- Provide short-circuit protection

- Enable safe maintenance by isolation

- Facilitate system switching and reliability

Applications in the Field

Low Voltage Switchgear is commonly used in:

- Commercial buildings

- Residential complexes

- Data centers

- Industrial plants (secondary distribution)

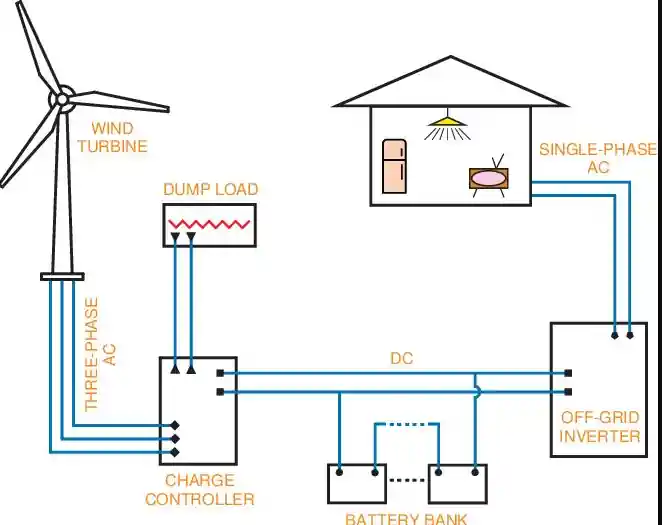

Medium Voltage Switchgear is used in:

- Power generation plants

- Transmission and distribution substations

- Renewable energy installations (wind/solar farms)

- Heavy industrial facilities

Market Trends and Industry Context

According to IEEMA and a recent report by Markets and Markets, the global switchgear market is projected to surpass USD 120 billion by 2030, driven largely by rapid urbanization, grid modernization, and the proliferation of renewable energy.

The increasing adoption of smart grid technologies and IEC 61850-based digital substations also fosters demand for modern MV switchgear with intelligent monitoring and diagnostics features.

Reference: Wikipedia – Switchgear, ABB Switchgear Overview

Technical Comparison

| Feature | LV Switchgear | MV Switchgear |

|---|---|---|

| Operating Voltage | Up to 1,000 V AC | 1 kV to 36 kV |

| Typical Current Ratings | Up to 6,300 A | Up to 4,000 A |

| Installation Location | Indoor (panels, cabinets) | Indoor/Outdoor (metal-clad, GIS) |

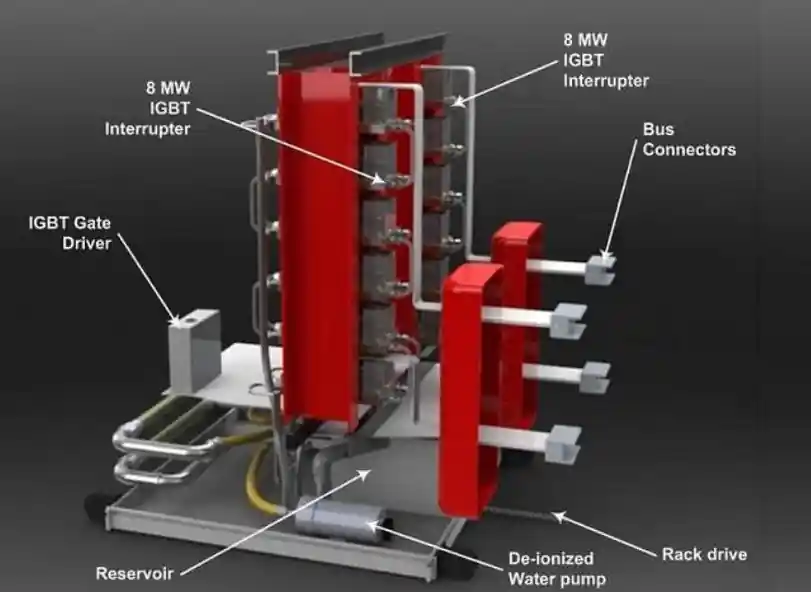

| Interruption Mechanism | MCCBs, ACBs | Vacuum, SF6, or Air circuit breakers |

| Insulation Type | Air | Air, SF6, or Solid Insulation |

| Maintenance Frequency | Low | Moderate to High |

Key Differences

- Voltage Class: As the name suggests, MV switchgear operates at significantly higher voltages than LV switchgear.

- Design & Insulation: LV equipment typically uses air insulation, while MV switchgear may require gas-insulated (GIS) or solid insulation to handle arc flash and thermal stresses.

- Space Requirements: MV gear is bulkier, often requiring dedicated switchrooms or outdoor enclosures.

- Safety Considerations: MV systems require more stringent safety protocols, often including remote operation, arc-resistant design, and detailed interlocking systems.

- Cost and Complexity: MV switchgear is more expensive and complex due to its insulation and protection technologies.

How to Choose Between MV and LV Switchgear

When selecting switchgear, consider the following:

- System Voltage: Use LV switchgear if the supply is below 1kV; choose MV if above.

- Load Size and Type: Large motors or transformers may necessitate MV systems.

- Installation Environment: Outdoor or mission-critical applications often require MV due to higher reliability.

- Regulatory Requirements: Refer to IEC or ANSI standards depending on your location.

Consulting OEM guidelines (like from Schneider Electric, Siemens, or ABB) and site-specific load calculations is essential.

Frequently Asked Questions (FAQ)

A1: Yes, if the machine operates below 1,000V and the fault level is within the interrupting capacity of the LV gear.

A2: Common options include air, SF6 gas, and solid epoxy. GIS (Gas Insulated Switchgear) is popular for compact designs.

A3: Not necessarily. While many MV systems are outdoor-ready, there are also indoor variants such as metal-clad or modular systems.

Understanding the differences between LV and MV switchgear ensures the correct equipment is specified for safety, efficiency, and regulatory compliance. Whether you’re powering a commercial facility or distributing energy across a national grid, matching the right gear to the voltage and load is fundamental to reliable operations.

For more detailed specifications, always consult technical documentation from manufacturers like ABB, SIBA, GE, and standards from IEEE or IEC.